How to Choose High Quality Carbon Raiser

High-quality carbon raiser generally refers to a carbon additive that has been graphitized. Under high temperature conditions, the arrangement of carbon atoms is in the microscopic form of graphite. Graphitization can reduce the content of impurities in the carbon raiser, increase the carbon content, and reduce sulfur content.

When choosing a high-quality carburant, the following issues should be paid attention to

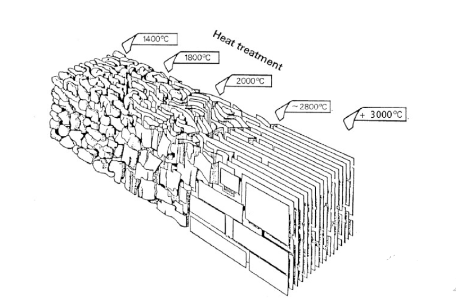

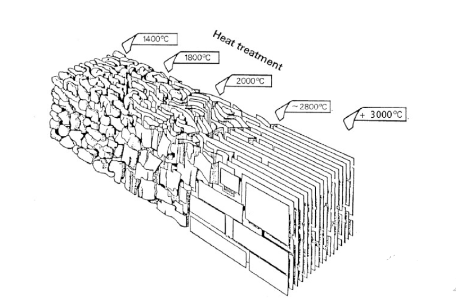

1. Try to use high-temperature graphitization carbon raiser as much as possible. The higher the treatment temperature, the better the graphitization effect, such as graphite electrodes or graphitized oil coke. Good carbon raiser have high absorption rate and fast dissolution speed, which is beneficial to reduce Energy consumption, and can effectively increase the nucleation core of molten iron and improve metallurgical quality.

2. Select carbon raiser with low impurity elements such as sulfur and nitrogen. The nitrogen content of the recarburizer with high sulfur content is also high. When the nitrogen content of the gray iron liquid iron is higher than the equilibrium concentration, it is easy to produce crack-like nitrogen pores, and the ductile iron liquid iron is easy to produce shrinkage defects in the thick-walled part, and the impurity content When it is high, it increases the tendency of casting slag inclusion.

3. According to different furnace sizes, choosing the appropriate particle size of carbon raizer can effectively improve the absorption speed and rate of carburant by molten iron.